Are Your Parts Fully Functional?

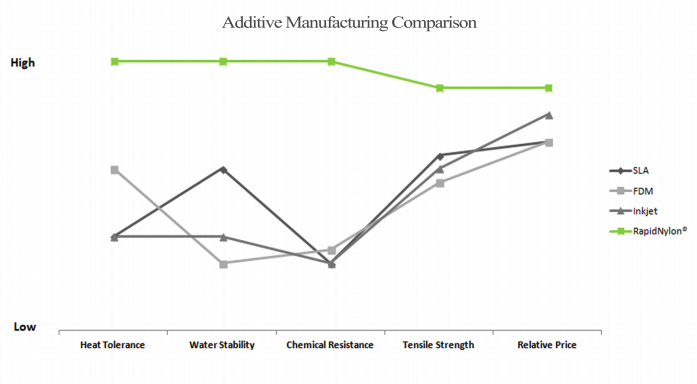

RapidNylon® parts are produced using a highly modified additive manufacturing process and a unique blend of high end material. Parts are extremely durable with high heat tolerances, exceptional strength capabilities and chemical insolubility.

Extremely Durable ● High Heat Tolerance ● Pressure Proof ● Liquid Insoluble

Technology

Technology

Material

Material

Infiltration

Infiltration

Applications

Applications